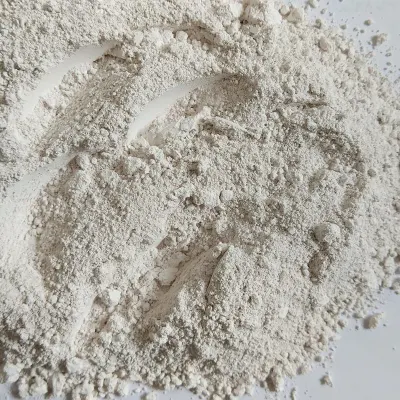

Chinese Manufacturers Suppliers Ceramic Glaze Zirconium Silicate Powder

Chinese manufacturers Suppliers Ceramic glaze Zirconium Silicate powder The zirconium silicate is produced using premium;

Basic Info.

| Model NO. | Zirconium Silicate |

| Appearance | Powder |

| Grade Standard | Industrial Grade |

| TiO2 | 0.15% |

| Fe2o3 | 0.1% |

| Whiteness | 92 |

| Specific Surface Area | 132000 |

| 0.15% | 7.5 |

| Zro2 | 65% |

| Ai2o3 | 0.4% |

| Sio2 | 32.8% |

| CAS No | 14940-68-2 |

| Application | for Ceramic (Sanitaryware, Tiles) |

| Transport Package | 25kg/Bag |

| Specification | Ceramic Zirconium Silicate |

| Trademark | HBCS |

| Origin | Hebei |

| Production Capacity | 5000000 Ton/Year |

Product Description

Chinese manufacturers Suppliers Ceramic glaze Zirconium Silicate powderThe zirconium silicate is produced using premium zircon sand. In the process, the techniques of impurity filtration and particle classification are applied to ensure a lower content of impurity and a more uniform particle size. Matrix has established a quality assurance system consisting of raw materials, production process and a comprehensive quality control of final products. The use of advanced analytical equipment, laser particle size analyzer and radiation monitoring equipment provides a strong guarantee for quality control and product improvement.

| ZIRCONIUM SILICATE Chemical Properties |

| Melting point | 2550 °C |

| density | 4,56 g/cm3 |

| form | nanopowder |

| Water Solubility | Insoluble in water, acids, alkali and aqua regia. |

| Merck | 14,10181 |

| Stability: | Stable. |

| CAS DataBase Reference | 10101-52-7(CAS Database Reference) |

| NIST Chemistry Reference | Zirconium silicate(10101-52-7) |

| EPA Substance Registry System | Silicic acid(H4SiO4),zirconium(4+)salt(1:1)(10101-52-7) |

Specifications

Zirconium Silicate ZrSiO4

58%, 63.5%, 65%, 66%

D50=1um D98=3.6um

Used in refractories

Specification

Content | |||||||||

ZrO2 | SiO2 | TiO2 | Al2O3 | Fe2O3 | Cr2O3 | P2O5 | V2O5 | S | Free Silica |

65% | 32.3% | 0.14% | 0.80% | 0.06% | 0.001% | 0.12% | 0.01% | 0.02% | 0.05% |

Usage

Used in refractories, glass furnace ramming mixes zirconium, castable, zirconia coating material, such as raw materials, precious stones, catalyst, cementing agent, glass polishing agents, resistance and electrical insulation, and refractory materials, glazes, glaze in ceramic whitening effect from the outside wall of imports of the production line has been widely applied

You may also like

Send inquiry

Send now